How Often to Service Your Custom Motorcycle: A Deep Dive into Maintenance Frequency

As a custom motorcycle enthusiast, you know there’s nothing quite like the rumble of an engine you’ve personally breathed life into, or the glint of chrome reflecting a vision you brought to reality. We get it. Here at Kinetic Motorcycles, we live for that unique roar, that one-of-a-kind aesthetic, and the unparalleled connection to a machine only a personalized build can offer. You’ve poured your heart, soul, and hard-earned cash into making your ride a true reflection of your spirit, from meticulously choosing every aftermarket motorcycle part to dialing in that perfect motorcycle exhaust.

But let's be straight: all that passion and precision goes to waste if your machine isn't consistently ready to hit the pavement. The question of "How often should you service a custom motorcycle?" isn't just about avoiding breakdowns; it's about preserving your investment, maintaining peak performance, and ensuring every mile you ride is as thrilling as the last. Unlike stock motorcycles with their neat, pre-defined factory service schedules, your custom creation marches to the beat of its own drum. And that means its custom motorcycle maintenance needs are as unique as the build itself.

Ignoring these nuances is a surefire path to unexpected roadside frustrations, compromised safety, and costly repairs that can quickly diminish the pure joy of your ride. At Kinetic Motorcycles, we believe that understanding your motorcycle service intervals is not a chore, but an integral part of the exhilarating custom lifestyle. This comprehensive guide is your essential roadmap, designed to strip away the guesswork and provide you with actionable insights for establishing the ideal custom motorcycle service schedule. As experts in customization and passionate riders ourselves, we're here to empower you to keep your masterpiece roaring strong, maximizing its performance and extending its lifespan for countless miles of open-road freedom.

Why Custom Motorcycles Demand Unique Service Schedules

Your custom motorcycle isn’t just a vehicle; it’s an extension of your personality, a mechanical work of art, a rolling testament to your vision. But this very individuality also means its motorcycle service intervals are rarely found neatly outlined in a generic owner's manual. Forget the "one-size-fits-all" approach – your custom machine demands a tailored plan.

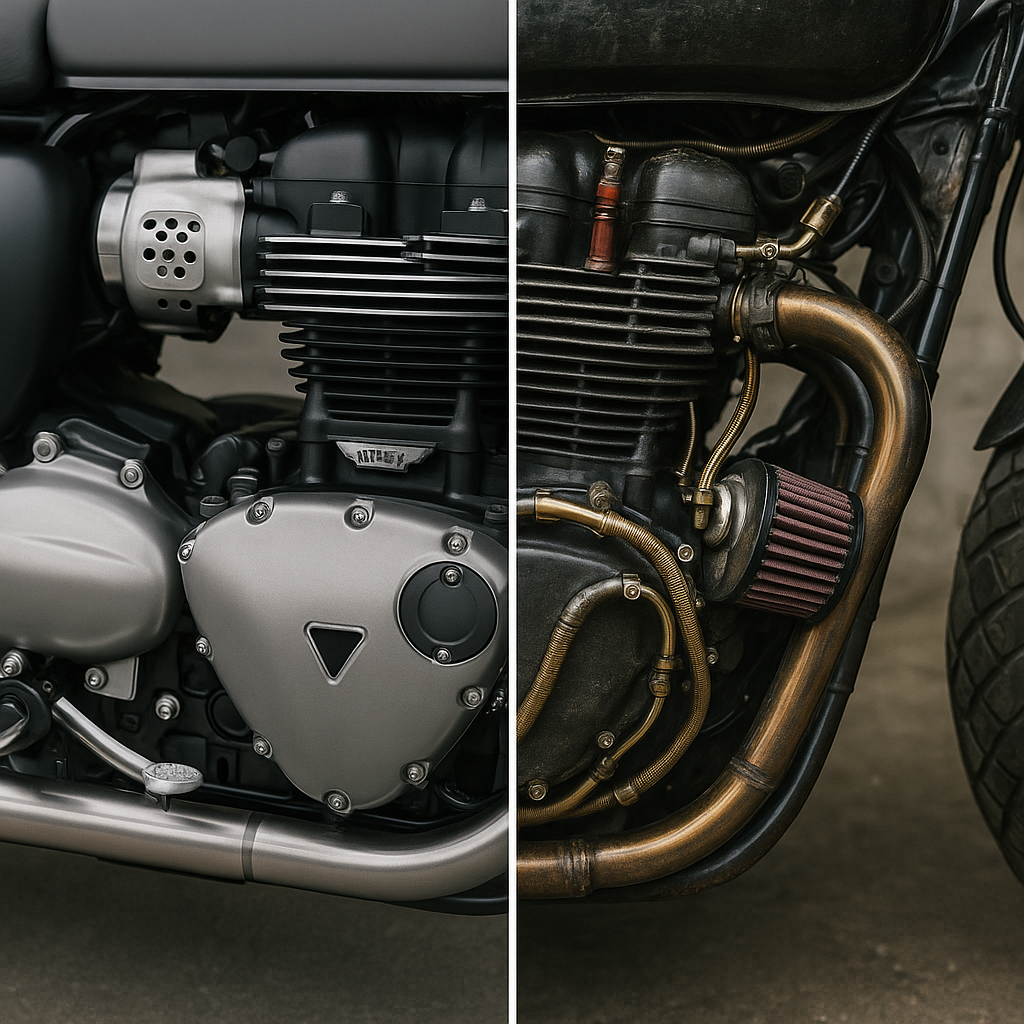

A. Beyond the Manual: Stock vs. Custom Components

Factory manuals are gold standards for stock motorcycles, no doubt. Original Equipment Manufacturers (OEMs) create these schedules based on exhaustive testing of their specific parts and configurations. They know exactly how long a stock clutch or a factory-spec brake pad should last under typical conditions.

But here’s the custom paradigm shift: when you start replacing those OEM parts with aftermarket motorcycle components, you’re introducing variables the original engineers never accounted for. These components – be it a high-flow intake system, a specialized motorcycle lighting setup, or an entirely new suspension – often have different tolerances, lubrication requirements, and wear characteristics. This means their service needs can diverge significantly from the factory specifications.

Pro Tip: Always keep the installation guides or manufacturer's recommendations for any aftermarket parts you install. They often include specific maintenance guidelines that supersede the OEM manual for that particular component. Don't just toss 'em in the "extra parts" bin!

B. The Impact of Modifications: Performance, Aesthetics, and Wear

Every modification, whether for raw power or killer looks, has an impact. It's not just about turning heads; it's about changing the very dynamics of your motorcycle.

Performance Upgrades: You cranked up the horses, right? Mods like engine tuning, camshaft changes, or a new fuel management system dramatically alter how your engine performs and the stresses it endures. More power almost always translates to more heat, increased friction, and higher stress on internal engine components. This can necessitate more frequent oil changes, earlier spark plug replacement, or even more frequent valve checks than a stock engine. For a deeper dive into making your ride rip, check out our guide on motorcycle performance upgrades.

Example: A highly tuned Harley Davidson Softail running a hotter cam and a performance exhaust system will put significantly more thermal stress on its engine oil. Where a stock engine might handle a 5,000-mile oil change interval, your beast might demand fresh oil every 2,500-3,000 miles to prevent premature wear and maintain its edge.

Aesthetic Changes: "Looks ain't everything, but they sure help!" We agree. But even purely cosmetic changes can inadvertently impact maintenance. Custom handlebars with internal wiring, relocated control cables, or a new battery box can affect cable routing, wiring integrity, or even accessibility for future maintenance. Poorly routed cables can chafe and wear, leading to electrical shorts, while tight spaces can make routine checks a nightmare.

Weight & Balance Shifts: Did you chop the frame, swap out the wheels, or add significant custom bodywork? These changes alter your motorcycle's overall weight distribution. This, in turn, impacts everything from tire wear patterns (uneven wear can point to balance issues) to suspension damping characteristics and even brake performance under different loads.

C. Riding Style and Environment: The Unseen Variables

Your custom motorcycle isn't a garage queen (unless that's your specific build style!). It's meant to be ridden, and how and where you ride it profoundly impacts its service needs.

Aggressive vs. Cruising: Are you always on the throttle, hitting those twisties hard, and braking late? Or are you mostly a cruiser, enjoying the open highway breeze? A motorcyclist who regularly pushes their custom machine to its limits – hard acceleration, aggressive braking, sustained high RPMs – will naturally generate more wear and tear on every single component, from the engine internals to the brake pads and tires. This means your performance motorcycle care will need to be significantly more frequent.

Climate Conditions: Your local climate is a huge factor. Riding in scorching summer heat, persistent rain, through dusty backroads, or in areas where road salt is prevalent will accelerate corrosion and wear on components like bearings, chains, and electrical connections. These conditions demand more frequent inspection, cleaning, and protection.

Storage Habits: How your custom motorcycle is stored during periods of inactivity (e.g., winter) is a direct extension of its service. If it's sitting exposed to the elements or in a damp environment, static degradation can set in faster than miles. Proper seasonal motorcycle maintenance for storage, including fuel stabilization, battery tending, and using a high-quality cover, is crucial for preventing accelerated corrosion and keeping it ready for that first spring ride.

Key Factors Influencing Your Custom Motorcycle Service Schedule

Building the optimal custom motorcycle service schedule isn't about pulling a random number out of thin air or blindly following a rigid calendar. For a custom build, it's about understanding a dynamic interplay of factors unique to your ride. Think of it like this: your motorcycle is a high-performance athlete, and its training regimen (maintenance) needs to be dialed in for its specific sport (your riding style and conditions).

A. Mileage Milestones: The Odometer's Truth

While factory manuals provide mileage-based intervals (e.g., "every 5,000 miles"), for a custom motorcycle, these are just a starting point. Your odometer isn’t lying, but it’s not telling the whole story.

Adjusting for Performance: If you’ve got a hopped-up engine, maybe a bigger cam, or a meticulously tuned fuel injection system, that powerhouse is pushing fluids and components harder. More power often means more friction and heat, which translates to accelerated oil breakdown. A highly tuned engine in a custom Harley Davidson Sportster, for example, might demand fresh oil and filter changes every 2,500-3,000 miles instead of the typical 5,000. It’s all about maintaining that performance motorcycle care and preventing premature wear.

Wear and Tear: High mileage, especially coupled with aggressive riding, puts increased stress on all moving parts: bearings, seals, suspension components, and driveline. Mileage is a primary indicator for comprehensive inspections and component replacements. A custom build ridden hard on extended road trips will need more frequent scrutiny of things like wheel bearings and brake pad wear than a lightly ridden show motorcycle.

B. Time-Based Intervals: The Calendar's Call

Even if your custom motorcycle spends more time under a cover than on the asphalt, time still takes its toll. Fluids degrade, rubber components dry out, and corrosion can quietly set in.

Annual Checks (The Bare Minimum): Regardless of how many miles you’ve logged, an annual service is a non-negotiable baseline for any custom motorcycle. This should include fluid checks and changes, a thorough battery assessment, and a top-to-bottom visual inspection. Why? Because even sitting still, things like brake fluid absorb moisture from the air, and engine oil can become acidic.

Fluid Shelf Life: Remember, fluids don’t last forever. Brake fluid and coolant are hygroscopic (meaning they absorb moisture) and degrade over time. Most manufacturers recommend replacing these fluids every 2-3 years, irrespective of mileage. That moisture in your brake fluid can lower its boiling point, leading to dangerous brake fade on a hot day.

Rubber & Gaskets: Think about those critical rubber hoses, seals, and gaskets. Over time, they can dry rot, harden, and crack, leading to leaks or component failure, even if your motorcycle isn't actively being ridden. This is particularly true for older custom builds or those exposed to harsh temperature fluctuations.

C. Component-Specific Needs: Aftermarket Demands

The beauty of a custom motorcycle is in its specialized parts, but those parts often come with specialized maintenance requirements that deviate from the factory standard.

1. Engine & Drivetrain Modifications:

Engine Tuning: If you’ve invested in aggressive cams, high-compression pistons, or even forced induction (like a turbo or supercharger), your engine is producing immense power and heat. These conditions push engine oil to its absolute limits. Consult with your engine builder or tuner; they often have specific recommendations for oil types and change intervals that go beyond the manual. Neglecting this is like running a marathon without proper hydration – you'll eventually break down.

Custom Clutch & Transmission: A heavy-duty clutch, necessary for handling increased horsepower, might require different lubrication or more frequent inspection of its friction plates and springs than a stock unit. Smooth operation ensures both longevity and precise control.

2. Suspension & Chassis Upgrades:

Aftermarket Forks/Shocks: High-performance aftermarket suspension units (like those from Ohlins, Fox, or Race Tech) often have specific service intervals for fluid changes, seal replacement, or even internal re-valving. These units are built for precision but also require it in their upkeep. Neglecting them leads to a harsh, uncontrolled ride, defeating the purpose of the upgrade.

Custom Swingarms/Frames: If your custom motorcycle features a modified or bespoke swingarm or frame, regular inspection for stress cracks, loose welds, or mounting hardware is absolutely crucial, especially on highly stressed points. These are structural components, and their integrity is paramount to your safety.

3. Electrical & Lighting Systems:

Custom Wiring Harnesses: Many custom motorcycles boast simplified or entirely new wiring harnesses. These require regular inspection for chafing, loose connections, or corrosion, especially if they're exposed to the elements or high engine heat. A small short can quickly become a big headache.

Motorcycle Lighting: While modern LED lighting (like our custom motorcycle lighting solutions) typically lasts longer than halogen, it’s still vital to ensure all your custom lights (headlight, tail, brake, turn signals) are functioning and securely mounted. Check connections regularly for moisture ingress, especially after washing or riding in the rain.

D. Riding Habits: Aggressive vs. Cruising

Your personal riding style is a huge determinant of wear and tear. Are you a weekend warrior or a daily commuter? A canyon carver or a highway cruiser?

Hard Riding: If you're frequently wringing out the throttle, braking hard, or carving corners like you're on a racetrack, you're putting immense stress on your engine, brakes, tires, and suspension. This kind of performance motorcycle care demands more frequent inspections and fluid changes. For example, a custom Triumph Thruxton that sees regular spirited canyon carving will require more frequent brake fluid flushes and tire checks than the same model used for leisurely Sunday rides.

City vs. Highway: Stop-and-go city riding can put more stress on your clutch, brakes, and cooling system due to constant engagement and lower airflow. Long highway cruises, conversely, might put more emphasis on tire wear, sustained engine temperatures, and vibration checks.

E. Climate & Storage Conditions

Where your motorcycle lives and breathes plays a significant role in its long-term health.

Extreme Temperatures: Riding or storing your motorcycle in consistently hot climates can accelerate fluid degradation, causing oils to thin and break down faster. Conversely, cold climates require specific winterization procedures to prevent freezing and corrosion.

Dust & Dirt: If you're out kicking up dust on backroads, particularly on a custom Scrambler or an adventurous Harley Davidson Dyna build, your air filter will get clogged faster. This necessitates more frequent cleaning or replacement to prevent engine starvation and maintain optimal performance.

Humidity & Salt: High humidity or exposure to road salt (if you ride in winter areas) will accelerate corrosion on exposed metal parts, fasteners, and electrical connections. This means more frequent cleaning, washing, and application of corrosion inhibitors are absolutely critical to prevent rust from taking hold.

The Core Components of Your Custom Motorcycle Service Plan

Building a robust custom motorcycle service schedule involves layering different levels of care, from quick pre-ride checks to in-depth annual overhauls. Think of it as a tiered approach – ensuring no critical area is overlooked and that your motorcycle always performs optimally.

A. The Daily & Pre-Ride Ritual: A Quick Safety Check

This fundamental routine shouldn't take more than 5-10 minutes, but it's your frontline defense against potential issues. It's about safety first, always.

The T-CLOCS Check: This classic mnemonic is your best friend. It stands for:

Tires & Wheels: Always check tire pressure (cold pressure is key!) and visually inspect for any damage, bulges, embedded debris, or excessive wear. Are your custom wheels true? Any loose spokes?

Controls: Give your brake and clutch levers a squeeze. Do they feel right? Is there proper free play? Twist the throttle – does it snap back smoothly?

Lights & Electrics: Verify all your lights are working: headlight (high and low beam), tail light, brake lights (check both front and rear brake levers), turn signals, and horn. Does your custom motorcycle lighting system fire up without a hitch?

Oil & Fluids: Quick check of accessible fluid levels like engine oil (often with the motorcycle upright and warm, check your specific manual), brake fluid reservoirs, and coolant overflow (if liquid-cooled). Look for proper levels and any obvious leaks on the garage floor.

Chassis & Chain/Shaft Drive: A quick visual for any loose fasteners, signs of leaks, or obvious damage. For chain drives, check chain slack.

Stands: Ensure your kickstand or center stand operates freely and retracts fully.

Pro Tip: Make it a Habit: This isn't just for long trips. Make it a ritual before every ride, even if it's just a quick hop across town. It takes minutes but can save you hours of roadside frustration or, more importantly, prevent a safety incident. For a deeper dive into overall preparedness, remember to review essential motorcycle safety gear.

B. Routine Checks (Every 1,000 – 2,500 Miles / Monthly)

These are the regular pulse checks for your custom motorcycle, crucial for catching minor issues before they escalate into major headaches. They should be performed more frequently if you’re riding hard or in adverse conditions.

Fluid Levels & Condition:

Engine Oil: Beyond just checking the level, look at the color and consistency. Is it milky (indicating moisture)? Excessively dark (indicating breakdown)? Or does it smell burnt? While you might not change it yet, these are signs to watch for.

Brake & Clutch Fluid: Check the reservoirs. Any signs of cloudiness or extreme darkness? This indicates moisture absorption and degradation, which directly impacts stopping power and clutch feel.

Coolant: For liquid-cooled custom motorcycles, ensure the coolant reservoir level is between the "min" and "max" marks when the engine is cold.

Tire Pressure & Tread: This cannot be stressed enough. Check cold tire pressure with a reliable gauge at least once a week, or before every major ride. Proper pressure is vital for handling, stability, grip, and tire longevity. Also, conduct a thorough visual inspection: look for uneven wear patterns, cracks (especially on sidewalls), bulges, or foreign objects embedded in the tread. Use a tread depth gauge; worn tires are dangerous.

Chain/Belt Tension & Lubrication:

Chain: If your custom ride is chain-driven (common on many Honda CB series or Triumph Scrambler builds), check its tension (refer to your manual or chain manufacturer's spec for the correct slack). A chain that's too tight or too loose can cause premature wear on sprockets and bearings. Clean and lubricate your chain thoroughly, especially after any rain or dusty rides, typically every 300-500 miles. A dry chain wears out faster and robs horsepower.

Belt: For belt-driven motorcycles (like many Harley Davidson models), inspect the drive belt for proper tension (check for deflection with light thumb pressure), fraying, cracking, or missing teeth. Misalignment can also cause premature wear.

Basic Fastener Check: Vibration from riding can loosen bolts. Do a general visual and tactile check of all accessible nuts and bolts. Pay special attention to critical areas like engine mounts, exhaust flanges, footpegs and shifters, and control clamps. A loose bolt can turn into a missing bolt, and then a major problem.

Pro Tip: Grab Your Wrench: Don't just look – put a wrench on a few key fasteners. You’ll develop a feel for what’s tight and what’s not. This regular proactive approach is a cornerstone of any good motorcycle upkeep guide. For a deeper dive into handling these frequent tasks yourself, check out our Ultimate DIY Maintenance Checklist.

C. Intermediate Service (Every 5,000 – 7,500 Miles / 6 Months – Annually)

This is where more in-depth maintenance kicks in, often aligning with a seasonal service interval, like prepping for summer or wrapping up the fall. It's about getting into the guts of your machine and making sure everything’s humming just right.

Oil & Filter Change (Engine, Primary, Transmission): Even if you’re not hitting those mileage markers, a full fluid change for all oil reservoirs is highly recommended at least annually. Old, acidic oil can corrode internal engine components, even while sitting. Fresh oil protects your engine, primary, and transmission from breakdown and ensures smooth operation. Always refer to your specific engine builder or aftermarket component manufacturer's recommendations for oil type and viscosity.

Pro Tip: Choose Wisely: For custom builds, especially those running hotter or with tighter tolerances, opting for a high-quality synthetic oil can offer superior protection and extended life. It's a small investment that pays big dividends in engine longevity and performance motorcycle care.

Brake System Inspection (Fluid, Pads, Lines): Your stoppers are arguably the most critical safety system.

Brake Pad Wear: Remove your calipers and inspect your brake pads. If they're worn below the minimum specification (usually a marked wear indicator or about 2mm thickness), it's time for new ones. Don't cheap out here!

Brake Lines: Inspect all brake lines for cracks, bulges, chafing, or leaks. Custom braided lines might be more durable, but they still need checks.

Brake Fluid: This is where that hygroscopic nature comes into play. If your brake fluid looks dark, cloudy, or like old coffee, it's absorbed too much moisture and needs to be flushed and refilled. Old fluid can lead to a spongy brake lever and dangerous brake fade when you need it most.

Clutch Adjustment & Inspection: Check your clutch lever free play and adjust as needed. A properly adjusted clutch prevents premature wear and ensures smooth, decisive engagement and disengagement. For hydraulic clutches, inspect the fluid level and condition, flushing if necessary.

Spark Plug Inspection/Replacement: Remove your spark plugs and inspect their electrodes for wear, fouling, or discoloration. These tell a story about your engine's combustion. Clean them if they look okay, or replace them if they're worn or heavily fouled. For performance-tuned engines, more frequent inspection (and potentially replacement with colder plugs) might be beneficial to maintain optimal combustion.

Air Filter Cleaning/Replacement: A clean air filter is essential for your engine to breathe freely. Clean reusable filters (like K&N) according to their instructions, or replace disposable ones. A restricted air filter chokes your engine, reduces horsepower, and can lead to rough running. This is especially true if your intake system is exposed to a lot of road grime.

Cable Lubrication & Adjustment: Lubricate your throttle, clutch, and front brake cables (if applicable) for smooth operation. Check and adjust their free play for optimal control response and safety. Sticky cables are not just annoying; they're a safety hazard.

Chassis & Suspension Inspection: Get down low and really look. Inspect for any loose bolts on the frame, engine mounts, and suspension components. Check for leaks from fork seals or rear shocks. Grab the front wheel and push/pull it sideways and forward/backward to check for play in the steering head bearings.

D. Major Service (Every 10,000 – 15,000 Miles / 1-2 Years)

This is the big one, the comprehensive overhaul that’s crucial for long-term longevity and peak custom motorcycle service schedule adherence. It involves diving deeper into the heart of your machine.

Valve Adjustment: This is a critical item for engines with adjustable valves (common on many Harley Davidson and Honda CB series models, as well as some Triumph setups). Incorrect valve clearance can lead to poor performance, excessive wear, unusual engine noises, or even catastrophic engine damage. Unless you’re a seasoned mechanic with the right tools, this is often a job best left to a professional.

Fork Oil Replacement: Your fork oil degrades over time, just like engine oil. It gets contaminated and loses its damping properties, leading to a harsher, less controlled ride. Replacing fork oil restores smooth suspension action and proper damping.

Wheel Bearing Inspection/Repacking: Lift your wheels off the ground and spin them, feeling for any roughness or play. If equipped with traditional bearings, inspect them for wear and repack them with fresh grease. If sealed, check for play. Worn wheel bearings can lead to instability and, in extreme cases, wheel lock-up.

Swingarm & Steering Head Bearing Service: These critical bearings are often overlooked. Worn steering head bearings lead to vague steering, a "notchy" feeling, and instability, especially at speed or under braking. Swingarm bearings affect rear wheel stability and handling. Inspect, clean, and lubricate or replace these as needed.

Full Fluid Flush (Brake, Clutch, Coolant): This is the time to completely drain and replace all hydraulic fluids (brake and hydraulic clutch fluid) and engine coolant. This ensures optimal performance and corrosion protection.

Comprehensive Wiring Harness Inspection: With many custom builds featuring simplified or entirely new wiring, a thorough inspection of the entire wiring harness is paramount. Look for chafing, corrosion (especially at connectors), loose connections, or brittle insulation. Pay extra attention to areas exposed to heat, vibration, or the elements.

Statistic: According to data from various roadside assistance providers, electrical system failures (including battery and wiring issues) are consistently among the top reasons for motorcycle breakdowns. Proactive inspection during major services can prevent you from being stranded.

Pro Tip: Document Everything: Keep a detailed log of all maintenance performed, including dates, mileage, and specific parts used. This not only helps you track your motorcycle upkeep guide but also adds significant value if you ever decide to sell your custom motorcycle. A well-documented service history is gold.

DIY Custom Motorcycle Maintenance vs. Professional Service

As a custom motorcycle enthusiast, the satisfaction of wrenching on your own machine is unparalleled. There's a deep connection formed when you know every bolt, every wire, and every fluid flowing through your personalized masterpiece. However, knowing your limits and strategically leveraging professional expertise is key to a sustainable, effective custom motorcycle service schedule. It's not about being a purist; it's about being smart.

A. Knowing Your Limits: When to Wrench, When to Call a Pro

The DIY Ethos: Many custom builders embrace the DIY spirit for basic maintenance, and rightfully so. Tasks like oil changes, tire pressure checks, chain lubrication, and swapping out footpegs and shifters are well within the grasp of most owners with a decent set of tools and a willingness to learn. Our Beginner’s Guide to Motorcycle Tools: Must-Have Essentials to Get Started can absolutely set you up for success here.

Complex Diagnostics & Repairs: This is where the line often blurs for custom rides. Modern custom motorcycles, especially those with advanced electronic fuel injection (EFI) systems, intricate engine tuning, or bespoke wiring, often require specialized diagnostic tools or in-depth, brand-specific knowledge that goes beyond basic mechanics. For instance, diagnosing a persistent "check engine" light on a highly tuned Harley Davidson Softail running a custom ECU, or rebuilding a high-performance aftermarket suspension unit, typically requires professional expertise and equipment that your home garage might not possess.

Safety-Critical Systems: Work involving braking systems (beyond pad replacement), critical engine internals (like valve adjustments), or structural frame modifications demands precision. Incorrectly performed work in these areas can lead to catastrophic failure, risking your safety and your investment. It’s one thing to change your oil; it’s another to mess with your calipers. For a comprehensive look at balancing your own ambition with professional help, dive into our DIY vs Pro custom motorcycle builds guide.

B. The Right Tools Make the Difference

Even for tasks you're tackling yourself, having the right gear isn't just about convenience; it's about accuracy, safety, and efficiency.

Essential Home Garage Setup: You don't need a sprawling shop, but a solid foundation of motorcycle tools is paramount. This includes a reliable torque wrench (critical for fasteners!), sturdy motorcycle stands (a must for tire, chain, and suspension work), fluid drain pans, specialty hex/Torx bits, and a good set of sockets and wrenches. Trying to do complex work with cheap, ill-fitting tools is a recipe for stripped bolts and frustration.

Kinetic Motorcycles Tools & Accessories: At Kinetic Motorcycles, we don't just sell killer custom parts; we understand the importance of quality tools that empower you. We stock a range of reliable motorcycle accessories and tools that help you tackle common maintenance tasks with confidence and precision, minimizing the customization challenges you might face. We believe that having the right equipment makes the process enjoyable and the results reliable.

C. Finding a Trusted Custom Shop (Kinetic Motorcycles Network)

Sometimes, the job is just too big, too technical, or simply beyond your comfort zone. When professional help is called for, especially for intricate custom work, engine tuning, or complex diagnostics, it's absolutely crucial to find a shop with real-world experience in customizing motorcycles, not just servicing stock models. You need someone who understands the nuances of aftermarket components, the specific demands of a highly modified engine, and the craft of a bespoke build.

Look for Expertise: Seek out shops that specialize in custom builds or specific platforms you're working with. Do they have experience with performance tuning Harley Davidson Sportster engines or re-wiring a custom Honda CB Series to perfection? Ask about their tools, their diagnostic capabilities, and their approach to custom work.

Kinetic Motorcycles Network: While we champion the DIY spirit and provide the highest quality parts, we also recognize the immense value of expert craftsmanship. We work with a network of trusted custom motorcycle shops and service centers that adhere to the highest standards. We can connect you with professionals who truly understand the intricacies of your custom Harley Davidson, Triumph, or Honda, ensuring your ride receives the specialized care it deserves to keep it performing at its peak.

Promoting Longevity: Beyond the Service Schedule

A well-defined custom motorcycle service schedule is the backbone of longevity, no doubt about it. But just like a champion athlete needs more than just workouts, your custom ride thrives on a few extra habits that significantly extend its life, maintain its aesthetics, and ensure countless miles of thrilling journeys. It’s about proactive care and making smart choices.

A. Quality Parts for Quality Upkeep

You wouldn't put cheap gas in a high-performance engine, right? The same goes for the components you choose, whether for a build or for maintenance.

The Foundation of Reliability: The best maintenance routine in the world won't compensate for shoddy parts. Investing in high-quality aftermarket motorcycle parts from reputable sources means they’re built to last, designed for proper fitment, and often come with clear service guidelines. Using cheap brake pads that dust excessively, or an inferior oil filter that restricts flow, will quickly undermine your diligent efforts.

Kinetic Motorcycles' Standard: At Kinetic Motorcycles, we don't just supply parts; we meticulously source components that meet rigorous standards for durability, performance, and aesthetic appeal. From our precision-engineered exhausts and robust grips to our cutting-edge lighting, every part is chosen to enhance your ride's capabilities and stand the test of time. This commitment to quality minimizes the need for premature replacements and contributes to a truly sustainable customization strategy.

B. Storage & Protection

Your custom motorcycle might be built to run, but how you treat it when it's not running is just as vital.

The Off-Season Impact: If you're a seasonal rider, how you store your motorcycle during longer periods of inactivity (think brutal winter months) is a direct extension of your maintenance. Proper seasonal motorcycle maintenance for storage, including fuel stabilization, battery tending, and proper covering, prevents accelerated degradation. Neglecting winterization can lead to fuel system gunk, dead batteries, and rusted components, making that first spring ride a costly headache.

Protective Gear: Investing in a high-quality, breathable motorcycle cover is essential, even if your ride is stored indoors. A good cover protects your custom finish from dust, incidental bumps, and moisture, ensuring it looks as good as it runs, season after season.

C. Riding Smooth: Impact on Wear

It might seem counterintuitive, but how you ride can significantly impact your custom motorcycle maintenance frequency.

Mindful Operation: While your custom motorcycle is built to be ridden hard, a mindful approach to operation can significantly reduce unnecessary wear and tear. This means avoiding excessive revving when the engine is cold, smooth clutch engagement (no brutal clutch dumps!), progressive braking rather than sudden grabs, and anticipating traffic rather than constant throttle on/off cycles. Every harsh input creates stress on components.

Pre-Ride Warm-up: Patience is a virtue, especially at startup. Allowing your engine and fluids to reach optimal operating temperature before pushing the limits ensures proper lubrication reaches all critical components, significantly reducing internal wear. Cold oil doesn't lubricate as effectively. Give it a few minutes to warm up and circulate.

Model-Specific Considerations (Kinetic Motorcycles Brands)

While general principles of custom motorcycle maintenance apply across the board, specific custom motorcycle platforms often come with their own quirks, common trouble spots, and nuanced maintenance considerations. At Kinetic Motorcycles, we understand these differences, offering tailored insights and specialized parts for the platforms you love to customize.

A. Harley Davidson Sportster, Softail, Dyna Service Pointers

Engine Type: Harley Davidson's iconic V-twin engines, especially the air-cooled Evo and Twin Cam variants found in many custom Harley Davidson Sportster, Softail, and Dyna builds, have specific heat management considerations. Due to their air-cooled nature, more frequent oil changes are crucial, especially in hot climates or with aggressive riding.

Primary & Transmission Fluids: Harleys typically have separate fluid reservoirs for the engine, primary, and transmission. Each requires independent checks and changes. Don't forget that primary fluid, which lubricates the primary chain/belt and clutch, is just as important as engine oil.

Belt Drive Inspection: Many Harleys utilize a belt final drive. Regular inspection of this drive belt for proper tension, any signs of fraying, cracking, or misalignment is key to preventing catastrophic failure.

Common Mod Impact: Aftermarket open intake systems or performance exhaust systems, while enhancing sound and power, can lean out fuel mixtures. This often necessitates professional engine tuning (e.g., a Dyno tune with a fuel management system) to maintain optimal engine health, prevent overheating, and truly unlock the performance motorcycle care you're after.

B. Triumph Bonneville, Thruxton, Scrambler Nuances

Air-Cooled vs. Liquid-Cooled: Older generation Triumph models were air-cooled and share heat management concerns similar to Harley V-twins. Newer, liquid-cooled models require diligent coolant system maintenance, including regular fluid checks and flushes.

Valve Clearances: Many Triumph parallel twins, both air and liquid-cooled, require regular valve clearance checks and adjustments. This often falls into the major service interval and is a critical step for smooth running and engine longevity.

Classic Wiring: For vintage or heavily customized Triumph builds, paying extra attention to aging or bespoke wiring harnesses is paramount. British electrics sometimes get a bad rap, but proactive inspection of connections, grounds, and insulation can prevent common electrical gremlins.

C. Honda CB Series: Classic Care for Custom Builds

Carburetor Maintenance: A huge number of classic Honda CB Series custom builds retain their original carburetors. Regular cleaning, synchronization, and proper fuel system maintenance (including fuel stabilization during storage) are vital to prevent fuel-related issues like clogged jets, poor idling, or rough running. Ethanol in modern fuel is a notorious carburetor killer.

Valve Adjustment: Like many Triumphs, numerous CB series engines have adjustable valve clearances that need periodic attention as part of their custom motorcycle service schedule. This job ensures correct valve timing and engine efficiency.

Electrical Reliability: While generally robust, older Honda electrical systems can sometimes suffer from age-related issues. Proactive inspection of all connections, ground points, and fuse boxes can prevent common failures and keep your custom ride's lights bright.

Parts Availability: For particularly rare aftermarket motorcycle parts or specific engine components on very old CBs, sourcing might require more planning and potentially a search through specialized forums or communities.

Conclusion: Invest in Your Ride, Ride for Miles

The journey of owning a custom motorcycle is deeply personal, an ongoing testament to your vision, skill, and passion. The satisfaction of a truly unique machine, the roar of a bespoke engine, the perfect handling on the open road – these are the rewards of the custom lifestyle. But this incredible experience is all underpinned by one critical, often overlooked, element: consistent, informed maintenance. Understanding how often to service a custom motorcycle isn't just about avoiding breakdowns; it's about preserving your investment, enhancing your riding experience, and extending the lifespan of every unique component you've painstakingly chosen. Neglecting these motorcycle service intervals is one of the top mistakes to avoid that can quickly dampen your custom dream.

Don't let the beauty of your custom motorcycle overshadow the necessity of its upkeep. Embrace a proactive custom motorcycle service schedule, invest in quality parts, and commit to vigilant care. Your machine, and your future adventures on the open road, will thank you for it.

Let's ensure your masterpiece is always ready for the open road. Ride safe, ride free!